Industry Training

The use of composite materials in aviation is increasing at a dramatic rate. These proven ultra-high performance materials are rapidly replacing traditional materials on aircraft ranging from high speed military aircraft to commercial airliners. Composites are becoming the standard aviation material due to their high strength, light weight and adaptability to manufacturing.

CES Hands-On Training

- Offers a training mechanism to facilitate a transition from traditional materials to composites.

- Programs ensure that critical maintenance personnel achieve a minimum level of expertise.

- Equipment and materials are portable. If you have basic shop facilities, we can provide in-house training.

- All of our instructors are A&Ps with many years of composite repair experience.

Course Outline

Introduction to Composites: Materials, matrix, uses, history, types of structures- laminates, sandwich construction.

Safety: Materials handling and storage, personal safety, aircraft safety, shop equipment layout.

Materials for a Repair: Vacuum bagging materials, adhesives, resins, fabrics and prepregs, tools and equipment.

Curing Systems: Room temp cure, heat lamps, ovens, heat guns, heat blankets, hot bonding equipment, vacuum systems

Cutting Tools: Uncured fabrics, cured fabrics, drilling, grinding, sanding

Damage Assessment, Inspection: Coin tap, visual, dye penetrant, ultrasound, hardness testers

Types of Damage: Classes of damage, SRMs, lightning strikes and prevention.

Repair Procedures: Material preparation, damage removal, water break test, lay-up materials, ply and ribbon orientation, preparation for cure, vacuum bagging, curing, step curing, ramp and soak curing, times and temperatures, inspection of cured repair.

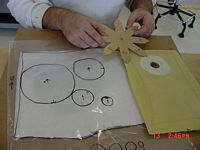

Student Projects: Hand lay-up, raw fabrics and prepregs, step cut and scarf sanding, vacuum bagging, curing, testing, drilling.